The Agile BioFoundry’s road to success was not a straight one; there were a few twists and turns along the way.

It all started well enough. It was 2013, and President Barack Obama had just given his State of the Union address, exhorting the country to make those investments in science that would strengthen U.S. manufacturing. Almost three thousand miles away, at Berkeley Lab, Mary Maxon, then the head of strategic planning and development for Biosciences and Jay Keasling, then Associate Lab Director for Biosciences, had already been discussing the idea of focusing on biomanufacturing. They encouraged Nathan Hillson, the lead of the Joint BioEnergy Institute’s (JBEI) Synthetic Biology Informatics Group, to put together a team and a Lab Directed Research and Development (LDRD) proposal to build the strategic groundwork that would be the foundation for a biomanufacturing institute.

LDRD Provides Seed Funding for a New Initiative

The team, which included fellow bioscientists Paramvir Dehal, Sam Deutsch, Nathan Hillson, Vivek Mutalik, and Trent Northen, submitted the proposal with the support of Mary, Jay, Adam Arkin (then the Director of the Physical Biosciences Division) and Eddy Rubin (then Director of the Joint Genome Institute). The Lab’s Deputy Director for Research Horst Simon was quick to recognize the opportunity and fund the project.

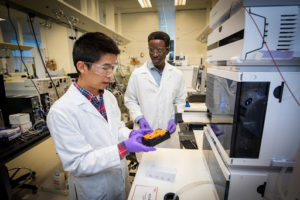

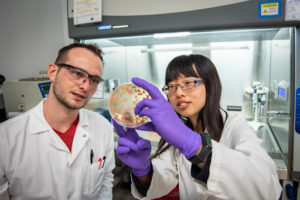

The project became the largest LDRD-funded project at the Lab to date. It had two objectives: 1) to refactor a metabolic pathway for the antibiotic actinorhodin, which would demonstrate the ability to make really large pathways, as this pathway constituted the largest refactoring attempt to date; and 2) to create combinatorial pathway designs for making the molecule violacein, a naturally-occurring pigment with antibiotic properties. This would demonstrate the ability to make vast libraries of combinations. The work on violacein in particular would involve training machine learning algorithms to learn from the variations explored so far and suggest new combinations to try.

The work led to tangible accomplishments and demonstrations of Berkeley Lab capabilities that the team could present publicly at conferences and include in programmatic development efforts. Before the team had generated new data to analyze, the members working on machine learning, namely Paramvir Dehal and Brian Olson, focused their efforts on building tools and conceptual frameworks for retrosynthesis, the process of working backwards from the desired final product to figure out how best to make that product (e.g. caffeine) from available precursors/feedstocks (e.g., glucose). This included applying the graph theoretical concept “betweenness centrality” to identify intermediate molecules that were most often found to be precursors to other molecules of interest. This concept of identifying strategic beachhead molecules, and working to enhance the routes to them, to accelerate and maximize access to products of interest across biochemical space, remains a core activity of the Agile BioFoundry to this day.

DARPA Funds a Pilot

As the LDRD project began to wind down at the end of FY 2015, the team, which under the leadership of Jay had expanded to include UC Berkeley scientists, began to cast around for the next tranche of funding. The Defense Advanced Research Projects Agency (DARPA) had been running its Living Foundries program, which aimed to streamline genetic engineering, and it was ready to build larger scale biofoundries.

DARPA was looking for a way to rapidly access different parts of biochemical space.

The Berkeley Lab team and its industry partners Amyris, Agilent, and Lockheed Martin worked together to submit a proposal to DARPA. The Lab had substantial relevant experience, and Amyris, one of the industry partners, was already a participant in a DARPA Living Foundry project. Recognizing these advantages, DARPA awarded the team a $1.5 million grant for a six-month Phase 1 project to develop a blueprint for a biomanufacturing platform dubbed the Berkeley Open BioFoundry (BOB).

So far, so good. The work continued to progress. And then the unthinkable happened. DARPA did not select the team for Phase 2, which would create the biofoundry itself.

“We were really distraught and disappointed,” said Nathan. “While we could speculate, we didn’t really understand why we weren’t selected. It was additionally perplexing that some of our industry partners put together a new team (without us) with similar ideas, and got the funding from DARPA.”

Regrouping

As the team recovered from this setback, Robin Johnston, then Deputy Chief Technology Transfer Officer at the Lab’s Intellectual Property Office, encouraged the team members to participate in the NSF’s Innovation Corps (I-CORPS) program hosted at the Haas Business School. Katy Christiansen, who had been involved in program development and strategy, Nathan, and Vivek formed a team to explore the “product market fit” for a future biomanufacturing institute through the program. That summer of 2015, they tested the institute’s value proposition with more than 100 companies, funding agencies, and academics.

“It was a lot of work—a full time job on top of our regular full time jobs,” said Nathan. “But it allowed us to document the strong demand for a biomanufacturing institute.”

And then the stars started to align. Beginning in 2014, Jay, Mary, and Blake Simmons, Chief Science and Technology Officer at JBEI, had already been talking about biomanufacturing to the Department of Energy’s Office of Energy Efficiency & Renewable Energy (EERE) and the Bioenergy Technologies Office (BETO). The idea came up at both the 2015 EERE National Lab Working Group and was then selected to be part of the formal slate of presentations made at the DOE Big Ideas Summit, where Blake teamed with Jay Fitzgerald, a Program Manager at BETO, to spearhead the development of the BioFoundry concept with the other partner National Labs and presented the concept to DOE leadership.

The Lab team turned their I-Corps interview results into a white paper that discussed the merits of a biomanufacturing institute, and shared it with EERE leadership as well as other DOE stakeholders. “BETO was interested because there were a lot of barriers to industrial biomanufacturing that needed pre-competitive research, and the institute could help lower these barriers. Starting in 2012, BETO started transitioning its research portfolio away from fuel ethanol and were looking for new ways to quickly expand to other targets like drop-in biofuels and chemicals,” said Katy.

“Our LDRD work backed up claims that we could do this work, and we were among the first national labs connecting AI/ML with biology,” continued Katy. “And at the time, there was not a lot available in terms of public facing biofoundry facilities, especially for the biofuels and biochemicals industry. The agencies were ready to move forward.”

At the end of the 2015 National Lab Big Ideas process, BETO informed Blake that they were interested in allocating resources to the concept and that there was some money available, and that they wanted a proposal within the week. Can we (Berkeley Lab and the partner national labs) do what we said we could do? The short answer was yes.

In the fall of that same year, the agency awarded $3 million in funding over one and a half years to the Lab and partners Sandia National Laboratories, Pacific Northwest National Laboratory, and National Renewable Energy Laboratory (NREL) for a pilot program. The team, along with the national lab partners, built out the science as well as held workshops with industry and developed a strategic vision that didn’t compete with industry.

The pilot was supposed to take 18 months, but after seeing the initial successes, the DOE decided at the end of one year to accelerate the program to establish a full BioFoundry, allocating $20 million a year to the program starting in FY 2017. And so the Agile BioFoundry (ABF) was born.

Today, seven national labs are part of the Agile BioFoundry, with the addition of Argonne, Los Alamos, and Oak Ridge National Laboratories. More than 70 researchers are on staff in total. The ABF operates as a distributed biofoundry in collaboration with industry and academia, with the objective of accelerating innovation and developing new biomanufacturing methods. In particular, the ABF focuses on developing industrially-relevant host microbes — bacteria and fungi — for the production of commodity chemicals and biofuels.

“This experience has taught me a lot about building research programs strategically,” said Nathan. “Many investigators are focused on finding funding opportunities and then applying for relevant opportunities. But Mary in particular understood that the way to grow large new programs is to develop a vision and to drive it. This meant creating white papers and socializing new ideas with funding agencies and the scientific community. This strategic approach can be a years-long process and brings risks, but it also brings potentially high rewards.”

“It’s been a long road, but now I feel like the biofoundry has grown up and flown the nest,” said Katy.

Tips for Submitting an LDRD proposal

I learned that getting an LDRD award is not just about putting forward a research proposal. It’s important to engage Division Directors and Associate Lab Directors, because they are the ones who will provide input into the decision making process.

It’s also important to ensure that you include, in your proposal, how the Lab will get its return on investment. We had that from Day One, because President Obama had talked about supporting an advanced biomanufacturing institute in his State of the Union address. That’s why the Lab was willing to provide the resources.

Nathan Hillson, Joint BioEnergy Institute’s (JBEI) Synthetic Biology Informatics Group

Where Are They Now?

The team that helped launch the Agile BioFoundry have continued to make significant contributions to research and industry. Here’s where they are today:

- Adam Arkin: Professor, Department of Bioengineering, University of California, Berkeley and Senior Faculty Scientist, Environmental Genomics and Systems Biology (EGSB) Division, Biosciences Area

- Katy Christiansen: Interim Area Science Deputy and Head of the Strategic Programs Development Group, Biosciences Area

- Paramvir Dehal: Computational Research Scientist, EGSB Division, Biosciences Area

- Sam Deutsch: Executive Vice President of Research and Early Development, Nutcracker Therapeutics

- Nathan Hillson: Lead Principal Investigator, Agile BioFoundry; Director of Synthetic Biology Informatics, Joint BioEnergy Institute; and Department Head of BioDesign and Senior Staff Scientist, Biological Systems and Engineering Division, Biosciences Area

- Jay Keasling: Professor, Chemical & Biomolecular Engineering, UC Berkeley; Chief Executive Officer, Joint BioEnergy Institute; and Senior Faculty Scientist, BSE Division

- Mary Maxon: Senior Fellow, Schmidt Futures (temporary assignment); Associate Laboratory Director (ALD) for Biosciences

- Vivek Mutalik: Staff Scientist, EGSB Division, Biosciences Area

- Trent Northen: Deputy Director, EGSB Division, Biosciences Area

- Brian Olson: Engineering Manager, Machine Learning, LinkedIn

- Eddy Rubin: Director, Science Corps, and Former Chief Scientific Officer, Metabiota

- Blake Simmons: Director of the Biological Systems and Engineering Division, Biosciences Area, and Chief Science & Technology Officer at the Joint BioEnergy Institute